The gauge inside radius die opening and minimum flange length are all interconnected through different equations and relationships the air bend force.

Moment require to bend sheet metal.

The force must exceed the material s yield strength to achieve a plastic deformation.

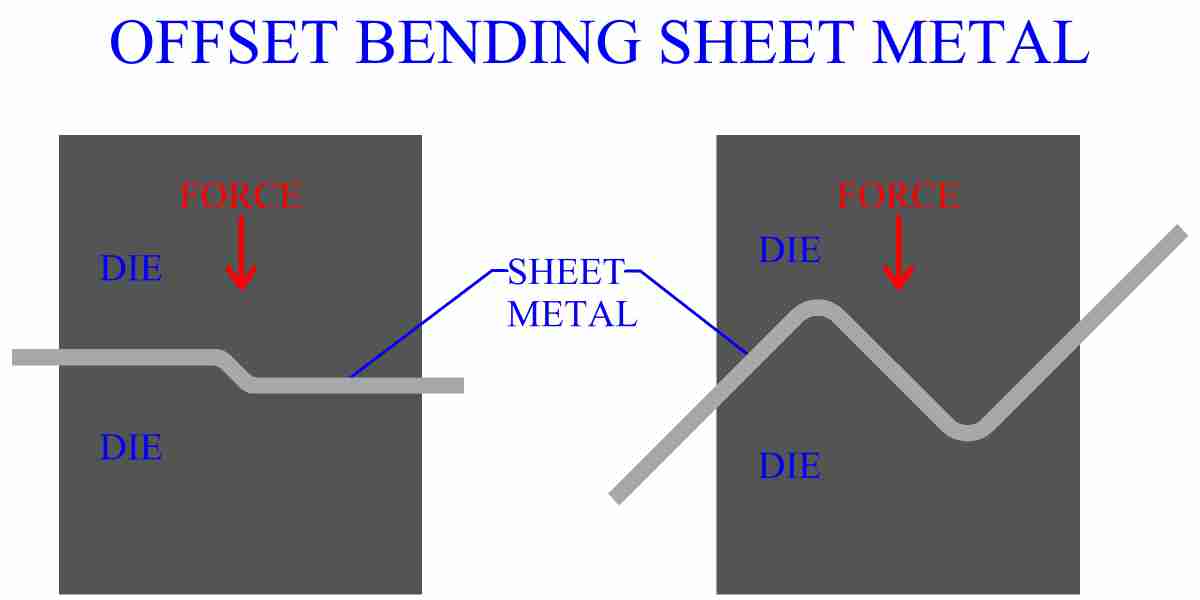

Bending is one of the most common sheet metal fabrication operations.

Actually it is an ideal condition but practically length and thickness changes up to some extent in bend area.

Every metal when subjected to a moment or couple it tends to bend.

In addition to creating a desired geometric form bending is also used to impart strength and stiffness to sheet metal to change a part s moment of inertia for cosmetic appearance and to eliminate sharp edges.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

The total strength of bending of a sheet is directly proportional to the length of bending.

Radius metal will crack at the outside heel of the bend.

Being able to read a bend force chart is crucial for any brake press operator and sheet metal engineer.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

The strength of the table is the force required to bend sheet metal up to 1 m in length.

Sheet metals have high bending ability which makes it versatile for various shaping and forming process.

On a 90 bend you should have about 3 to 4 of spring back however as this material work hardens very rapidly spring back also increases.

Calculate the required force to bend a piece of sheet metal using v bending a process in which a v shaped punch presses the sheet into a v die.

Bend allowance is the amount of metal to be added to the total layout.

It only changes shape of the work piece.

This is done through the application of force on a workpiece.

The bending force can be calculated from the sheet thickness die opening bend length and the ultimate tensile strength of the material.

Radius of a bend is determined by the hardness and thickness of the metal.

When bends are made smaller than the required min.

The most important considerations when bending metal is the min.

The material will work harden and you should try to get your forming done with as few press strokes as possible.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.